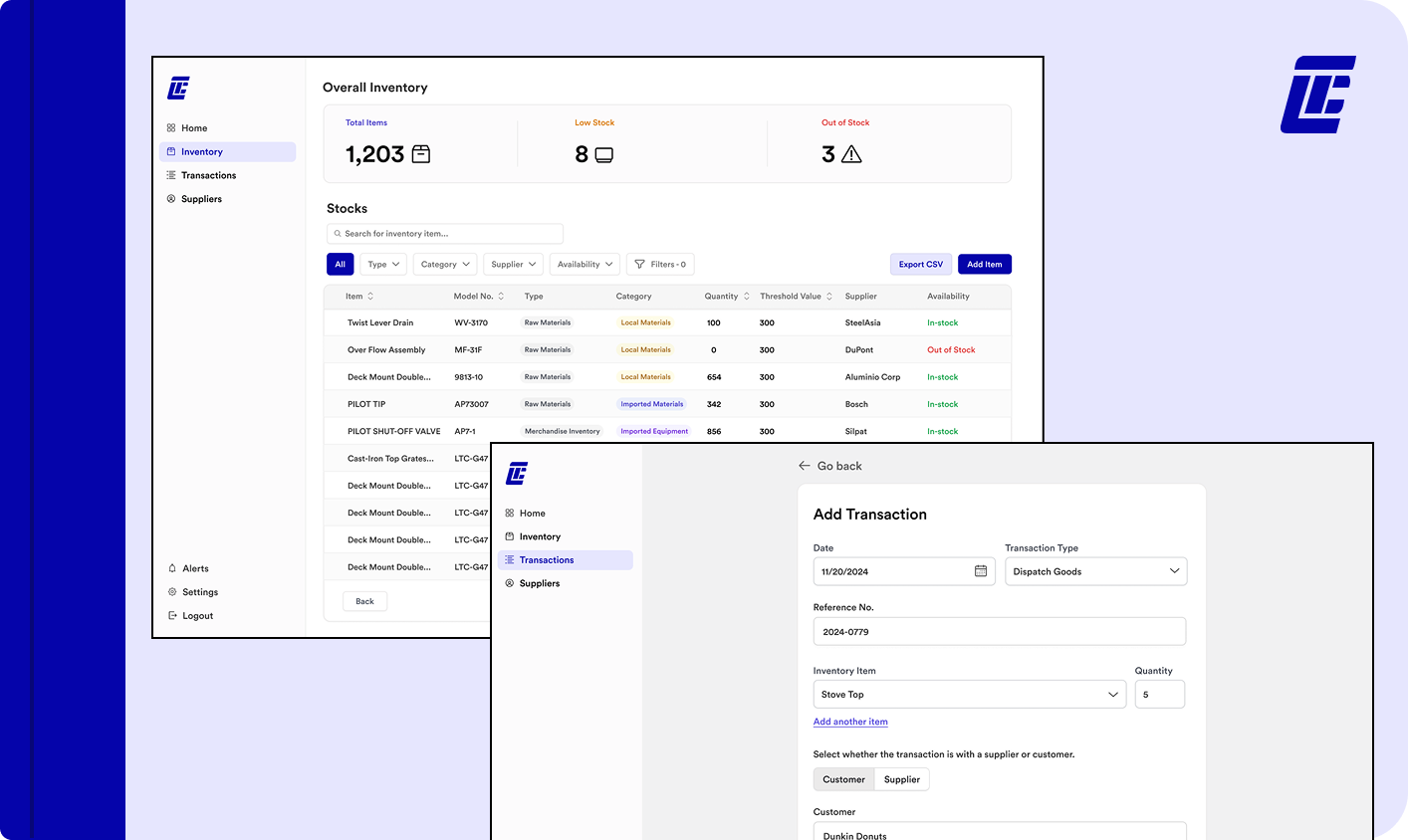

Lowtemp: Digitalizing inventory management for a leading kitchen equipment supplier

As the team's leader, I led requirements analysis before solely designing and developing the inventory management system for Lowtemp Corp, who serves food giants like TongYang and Dunkin Donuts.

Project Duration

June 2024 - May 2025

Industry

Enterprise

Role

Project Manager & Lead Developer

Team Context

Snatch and Solve (Six members)

The Problem

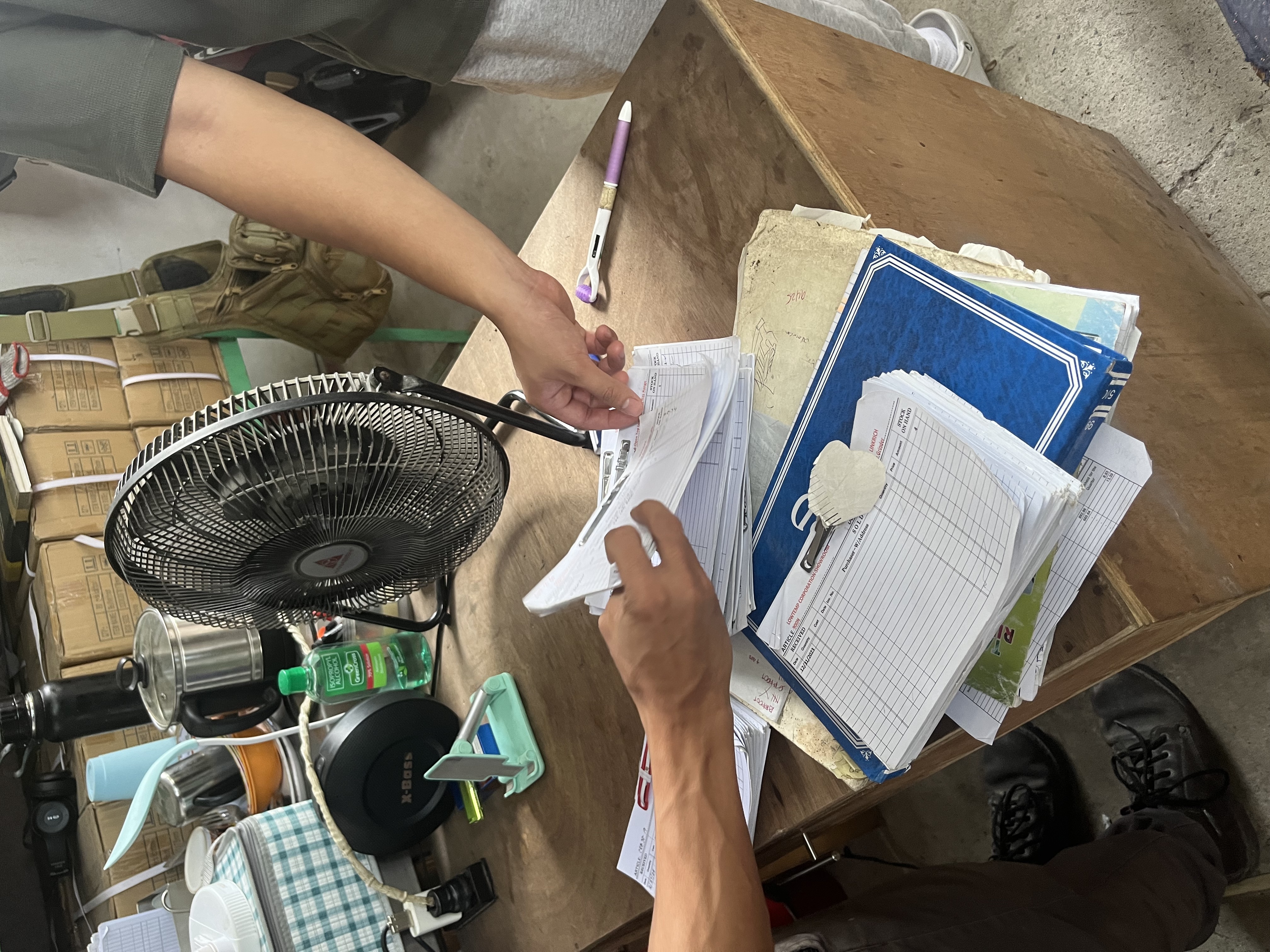

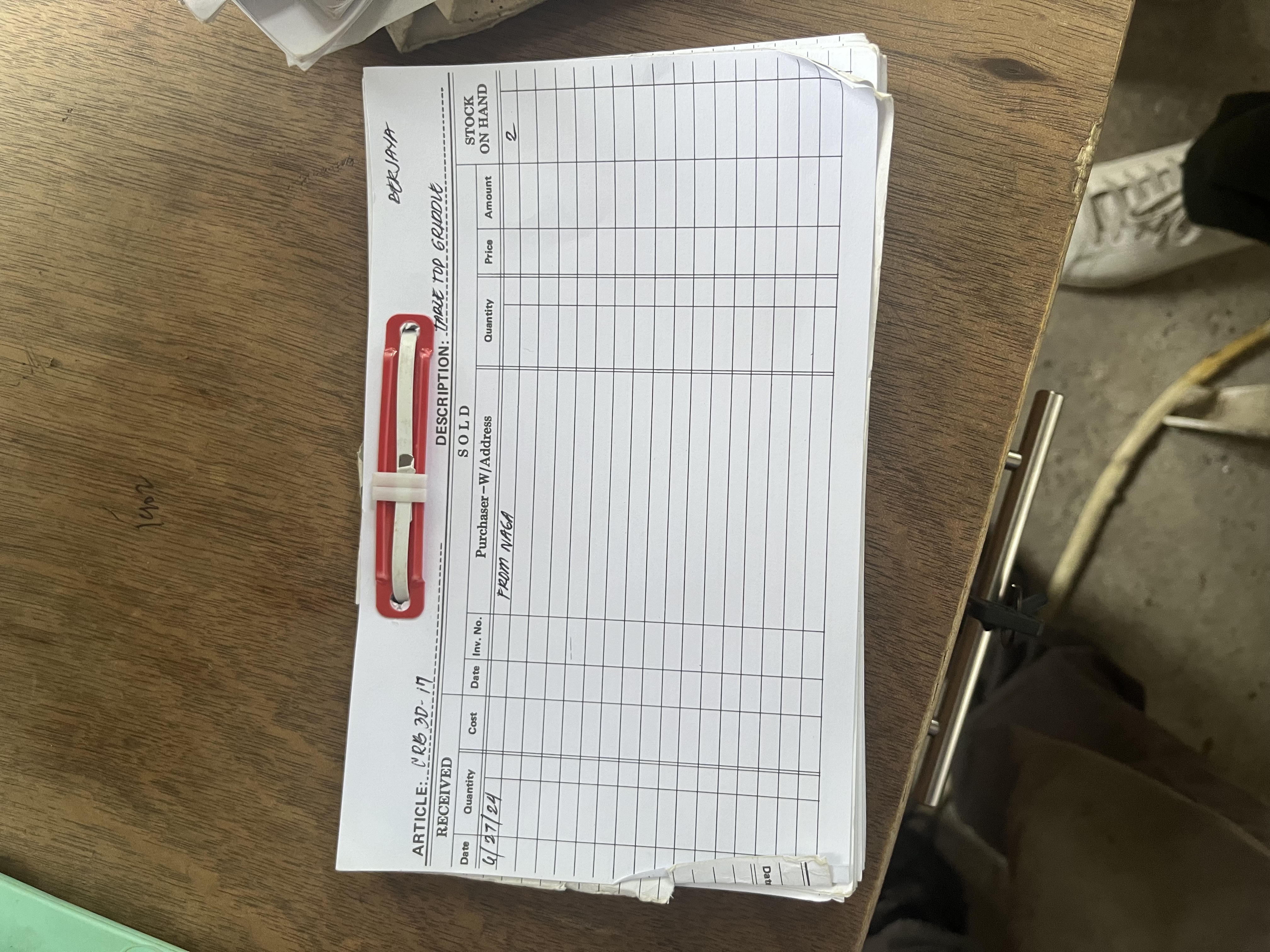

Lowtemp's accountant was drowning. Managing inventory for the Philippines' biggest kitchen equipment supplier on paper while also doing... well, accounting. 15% of their orders had errors, customers were pissed, and money was walking out the door.

When we first met Mr. Arven Realda, Lowtemp's accountant and inventory manager, he pulled out a stack of handwritten stock cards and said, 'This is how we've been doing it for years. It works, but...' He trailed off, gesturing at the chaos of papers scattered across his desk. That 'but' became our entire project brief.

The Process

We went to their warehouse in Antipolo and documented their processes. We wanted to put on the hat of being an employee so our solution could fit their current workflows.

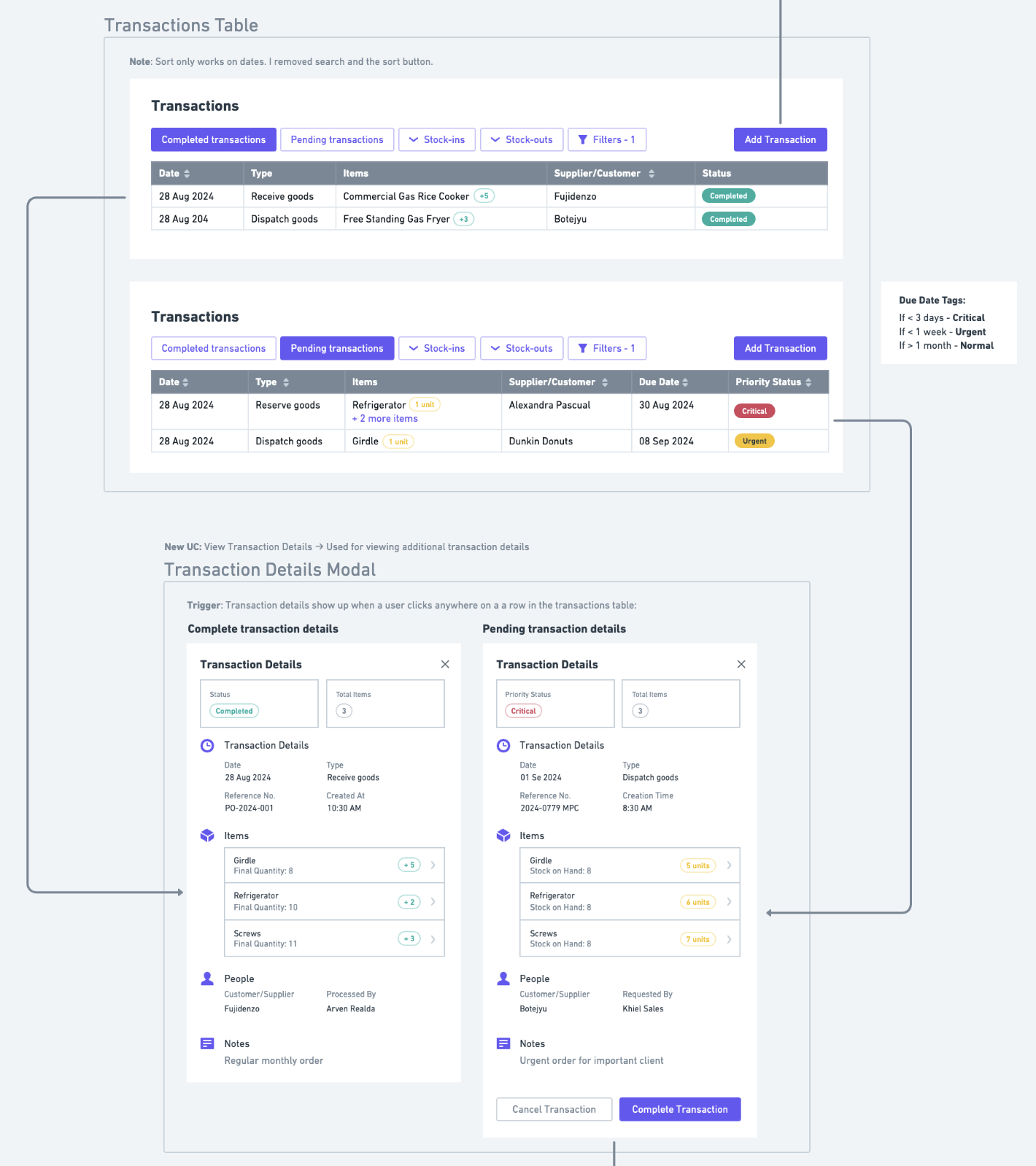

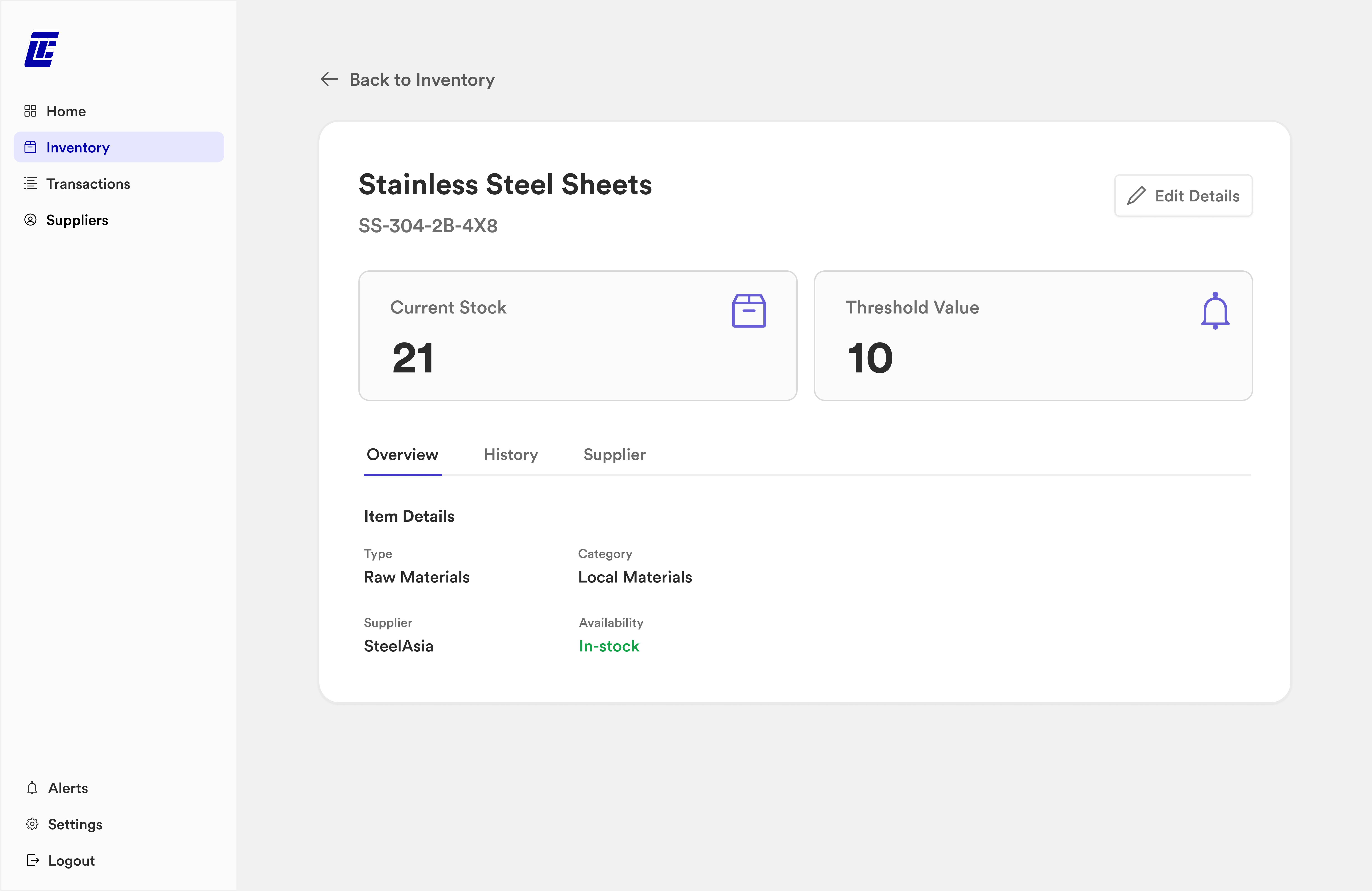

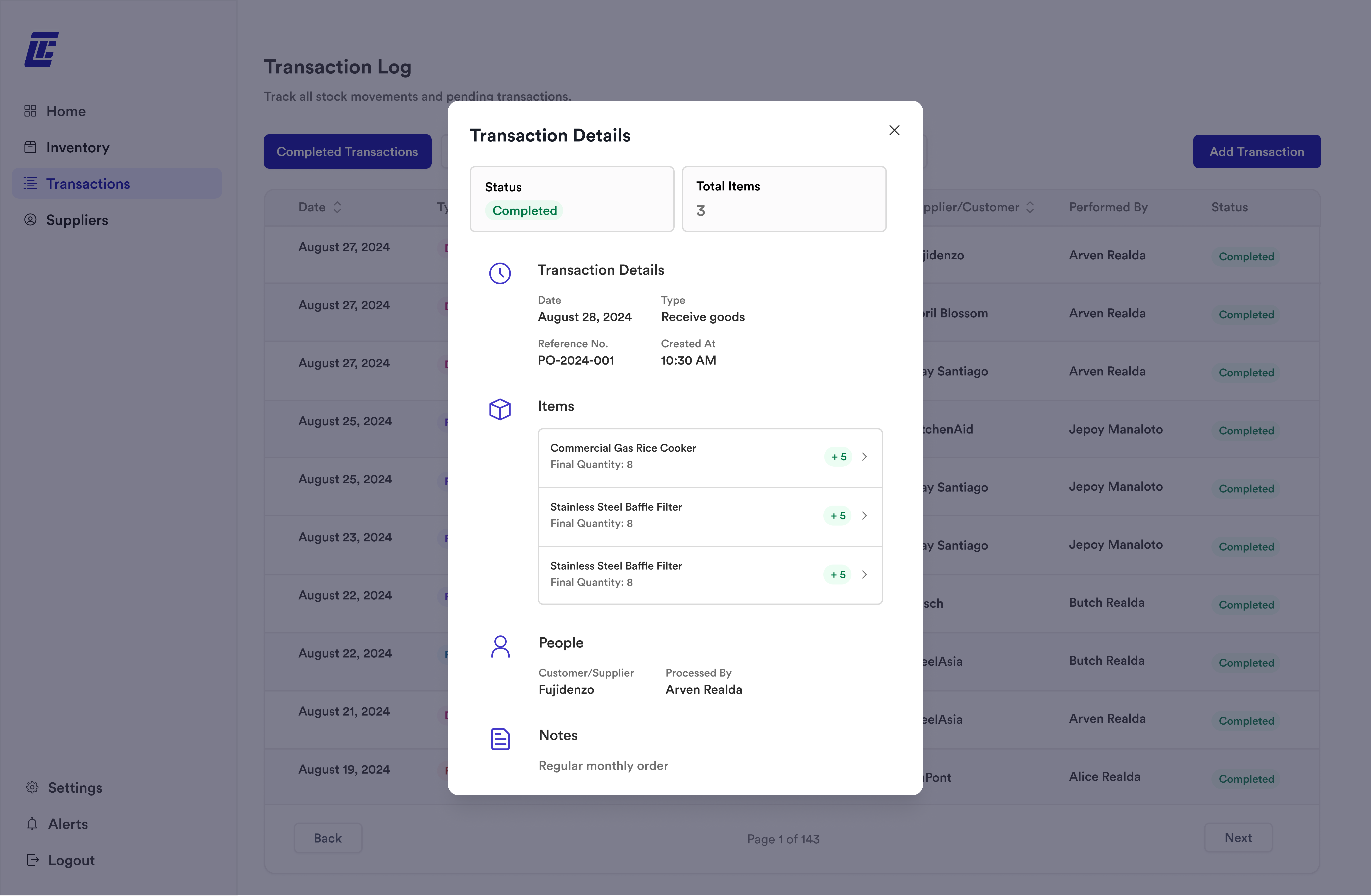

After racking our brains for what was essentially the "Product Requirements Document," we defined functional requirements and data flow diagrams. The focus was on how transactions affect inventory stock while retaining data integrity - no editing transactions, proper audit trails, the works.

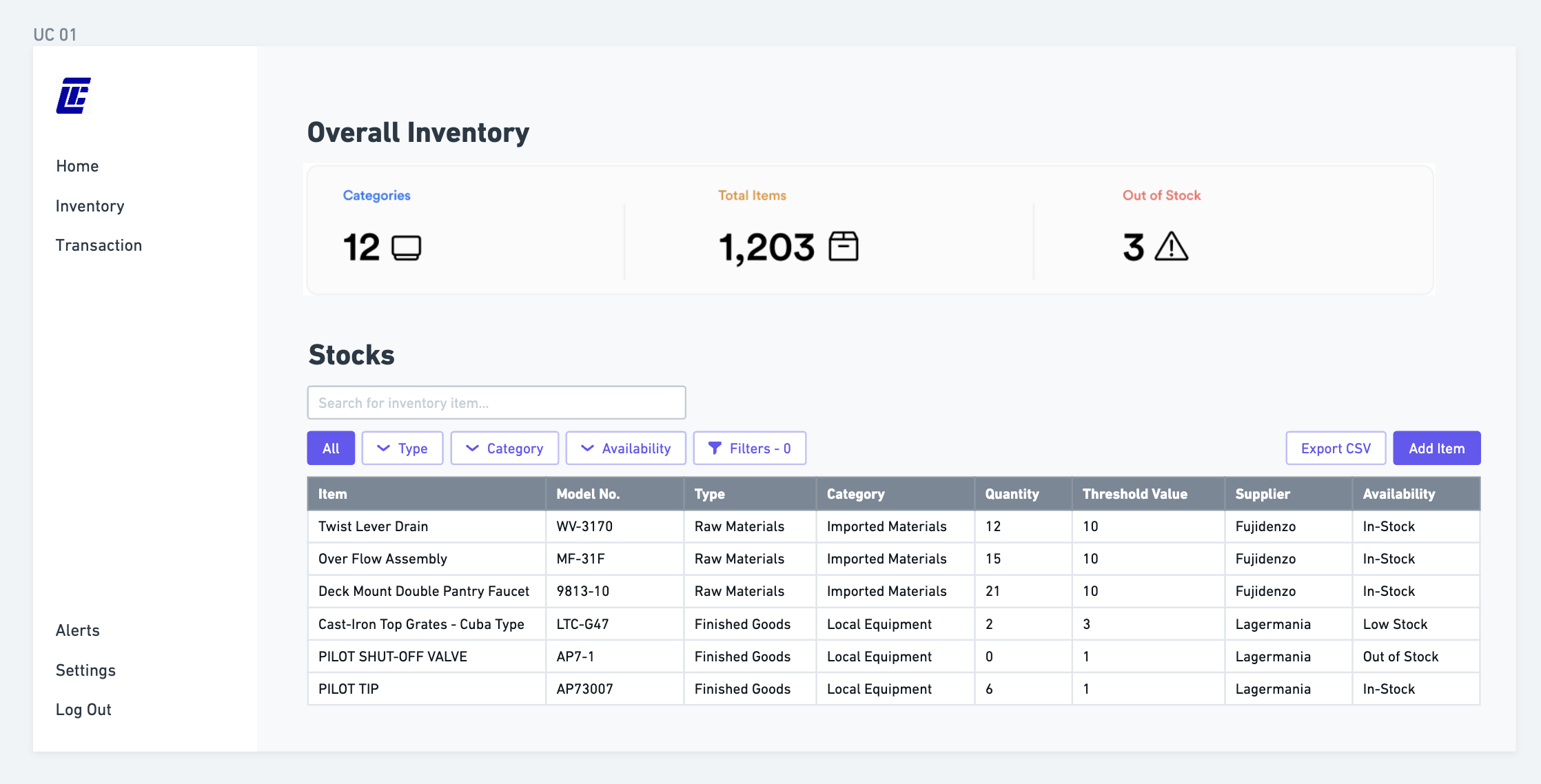

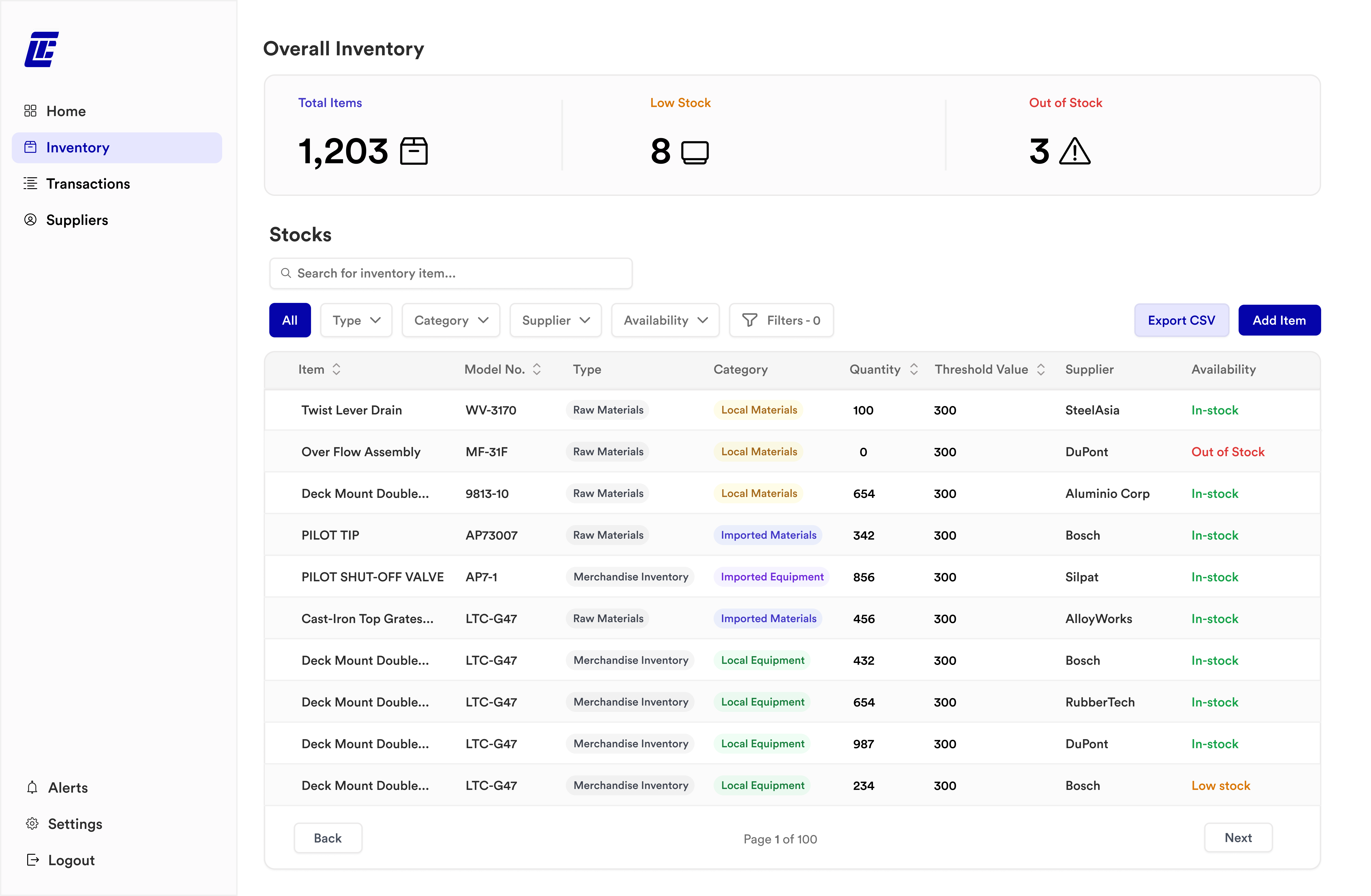

Finally, we designed the interface with one principle: simple and straightforward. No frills. Everything warehouse staff needs should be instantly readable at a glance. Nothing hidden for the sake of "minimal" design. These were the initial wireframes on Whimsical.

The wireframes became our shared language for discussing complex inventory flows. Each screen had to account for stock-ins, stock-outs, audit trails, and user permissions—business rules that weren't immediately obvious to someone outside manufacturing.

The Struggle

My biggest struggle? Designing a system that wasn't intuitive to me. Manufacturing wasn't familiar territory. Even after months, the terms were flying over my head. Stock-ins? Stock-outs? Merchandise goods? How would that look information architecture-wise?

Every design decision went through Mr. Arven first. "Would your warehouse staff actually use this?" became our constant refrain. He'd squint at our mockups and say things like, "The guys won't scroll down - they need everything visible at once." Pure gold for our design process.

It wasn't easy designing solo. I made sure to collate concerns as they popped into my head and sent them to our client liaison. The earlier, the better.

Development

Our final term involved building and testing the system. I planned sprints and we managed to finish early while producing quality output. The struggle was solo dev... I coded the first page, structured it for scalability, and gave Cursor the juice to assist with other pages. First time using Cursor—learned a lot.

Our professor pushed us to deploy on AWS with Docker and that was the most struggle I've ever had. But the challenge pushed me to deliver.

Eventually, we developed every functional requirement in under two months. Squishing bugs alone and implementing error validation are experiences I'll never forget.

The Moment of Truth

When we demoed the final system, Mr. Arven's reaction was immediate: 'Finally, something that makes sense.' He could navigate it intuitively, which felt like the biggest validation after months of back-and-forth.

Implementation is scheduled for June-September 2025 with a phased rollout strategy. We'll be monitoring error reduction and time savings closely. The paper chaos that defined their process for years is about to become a digital workflow that actually makes sense.

Takeaways

1. Start early, validate often. You'll always have assumptions. The sooner they're validated, the better your decision-making and your overall design would be.

2. Stay flexible while rigid. Have design principles to guide you, but don't get attached to old designs. The more you iterate, the better.

3. No shame in asking for help. This is a team-effort. Delegate according to how everyone wants to grow, their strengths, and be aware of weaknesses to fill-in each other's gaps. Don't tank everything!

4. AWS/DevOps is hard! 😅 But I want to learn more about IT infrastructure and how computers work under the hood because of it.

From someone who had no idea how inventory management works, it feels second nature to me now, along with integrating design and development requirements to our client's needs.